Innovation in Production Process, Design and Evaluation Technology for Ultra-lightweight Mass Production Automobile

In this research area, ISMA’s goals are to establish the basic technology for high speed molding of large members of thermoplastic CFRP for application to massproduced automobiles, and practical application and expanded use in automotive structures by applying a hybrid molding technology for CFRP and various high strength/high functionality materials. Trial manufacture of a thermoplastic CFRP chassis was carried out in 2017 (see photo on p. 2), and a 10 % weight reduction in comparison with the conventional aluminum chassis was achieved. ISMA is also developing an energy saving technology with superior Life Cycle Assessment (LCA) performance based on the development of a CFRP recycling technology.

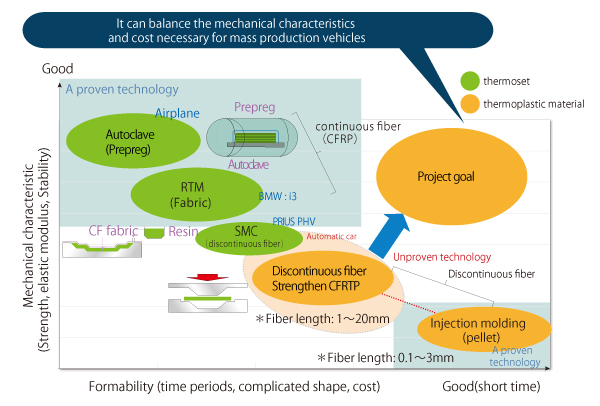

Target for development of CFRTP

LFT-D (Long Fiber Thermoplastic – Direct) Method

Research Achievements

Trial Manufacture of Thermoplastic CFRP Automobile Chassis

A 10 % weight reduction in comparison with an aluminum chassis for the target vehicle was realized, while maintaining the same levels of strength and stiffness.

Prototype of carbon fiber reinforced thermoplastic (CFRTP) automobile chassis

Construction of LFT-D High Speed Forming System for Large CFRTP Products

A LFT-D (Long Fiber Thermoplastic – Direct) high speed forming line, consisting of kneading/extrusion, heat-insulation transport, material handling robot and high speed press sections, was constructed.

Large LFT-D (Long Fiber Thermoplastic – Direct) high speed forming system