Development of Welding and Joining Technology for Multi-Materials Structured Car Body

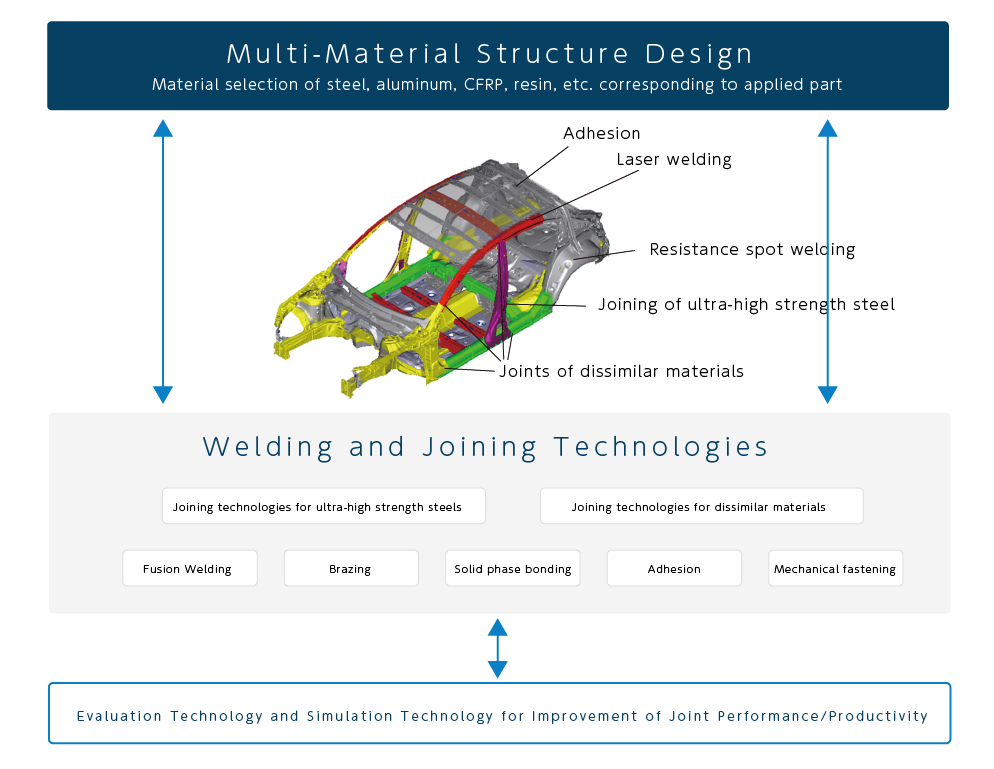

Various joining processes of fusion welding, brazing, solid phase bonding, adhesion and mechanical fastening have been developed for similar/dissimilar material joining of structural parts. However, from the viewpoints of joint performance, productivity and cost, those existing joining processes are not sufficient for implementing as the practical joining process in the car body production line. In this research and development, we are working on the establishment of friction stir welding and/or fusion welding which can be applied to joining hard-to-join materials such as ultra high strength steels including medium/high carbon steels and titanium alloys, and dissimilar material joining of metal to CFRP, together with in-situ observation and modeling of joining processes, and evaluation of joint performance. For dissimilar material joining, ISMA began the development of adhesion process for structural materials from FY 2017. In collaboration with multi-material design technique, we are conducting the development with basic research on welding and joining processes that demonstrate suitable joint performance corresponding to the material selection, aiming to realize the innovative joining technology with excellent cost competitiveness practically used in the car body production.

Conceptual Image of Development

Research Achievements

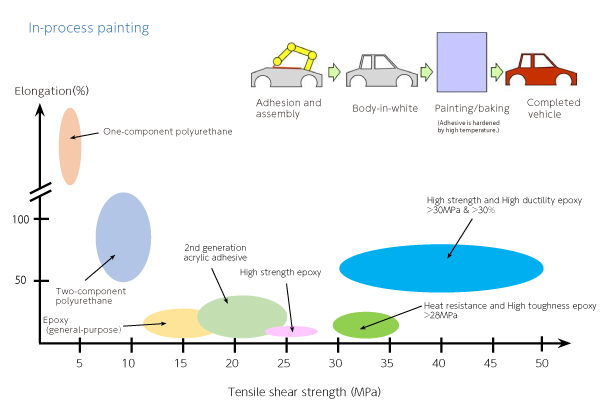

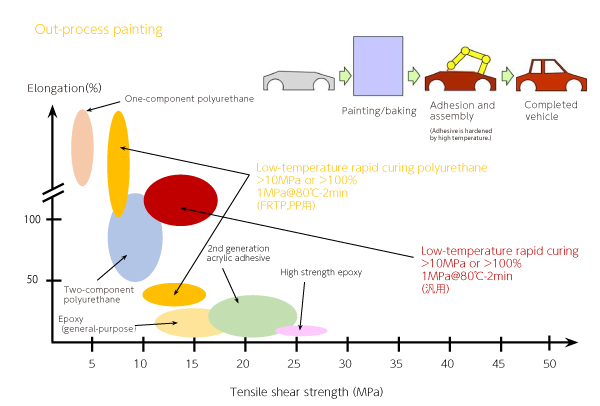

Development of Adhesive Joining Technology for Structural Materials

Adhesive joining, which can secure structural rigidity with minimal deformation at a comparatively low process temperature, is suitable for realizing multi-material structures. To solve the problems of joint strength, durability and productivity, ISMA is now developing new adhesives and conducting to elucidate the adhesion mechanism and establish an evaluation method of the adhesion quality, and develop a technique for improving bond durability.

Target performance (In-process painting)

Target performance (Out-process painting)

Fundamental Research on Friction Welding of Medium and High Carbon Steel

A technology that enables joining of medium and high carbon steels with carbon-contents of 0.3 % or more, which was difficult to join until now, is under development.

Research Achievements

Development of Two-Side Double-Action Friction Stir Welding (Flat FSW) Technology

ISMA is developing a flat FSW method that improves joint performance by using a double-action tool. We have also succeeded in 3D visualization of the plastic flow pattern during FSW by using an X-ray transmission system.

Flat FSW system (left) and X-ray transmission device (right front)

Medium and High Carbon Steel / Development of Friction Spot Joining Technology for Medium and High Carbon Steel

Development of a joining robot system and joining tool for hard-to-join ultra-high strength steel sheets was carried out.(Completed in FY 2017.)

Research Achievements

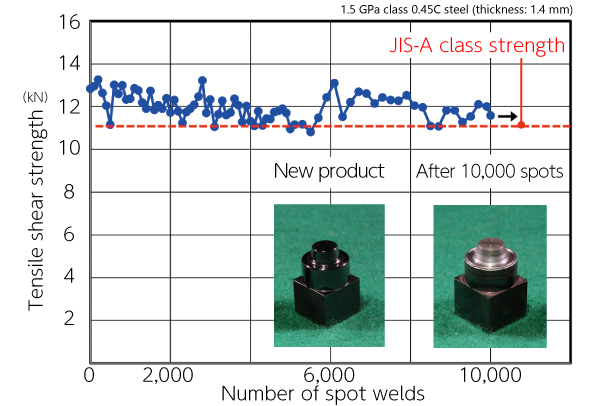

Developing Long-life Tool for Friction Stir Joining (FSJ) of Ultra-High Strength Steels

In this R&D, at the end of FY 2017, the durability of a tool that had initially reached the end of life at 204 spots in a test using 1.2 GPa tensile strength (TS) class steel sheets was improved so that use for more than 10,000 spots is now possible with 1.5 GPa TS class steel sheets.

Result of tool durability test using 1.5 GPa class steel sheets