Development of Energy-saving, High-productivity Carbon Fiber Production Process

To innovate the current carbon fiber production process, in which acrylic fibers are oxidized at several hundred degrees (Celsius) in the air and then carbonized at high temperature in nitrogen gas. ISMA aims to establish the basic technologies for the energy-saving, highly productive carbon fiber production process. To date, we have succeeded in synthesizing the world’s first solvent-soluble flame-resistant polymer. In parallel with this, we have also realized high speed carbonization of flame-proofed large-tow fibers within a timeframe of seconds, a feature of direct heating utilizing microwave. We are aiming to attain a large-tow (48K) carbon fiber with performance surpassing an elastic modulus of 240GPa and strength of 4GPa with a single filament diameter of 7μm.

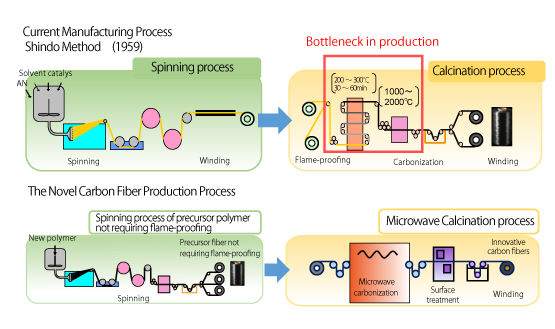

Comparison of current manufacturing Process and the Novel Carbon Fiber Production Process

Research Achievements

Development of New Carbon Fiber Precursor Compound

The world’s first solvent-soluble, flame-resistant polymer was synthesized successfully, and the basic technology for spinning was established with 6K filaments. As physical properties of the carbon fiber (CF), an elastic modulus of 240GPa and elongation of 1.5% were achieved with a single filament diameter of 5μm.

Spinning process of precursor polymer not requiring flame-proofing

Development of Carbonization Process by Microwave Heating

High speed carbonization in a time-frame of seconds, a distinctive feature of direct microwave heating, was attained even with flame-proofed large-tow fibers. We have found that carbon fibers with large tow (48K) and stable quality can be obtained by this carbonization process. To understand carbon fiber structure accompanying this process and its correlation with mechanical properties, a new technique has been developed. Now we can evaluate microwave irradiation conditions, fiber heating mechanism and differences in structural changes in detail and quantitatively. The technological basis for realizing stable carbonization has been established.

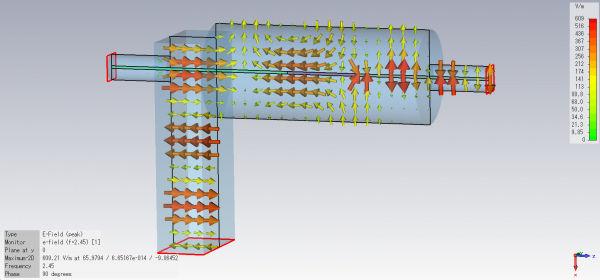

The equipment for microwave carbonization

Electric field simulation