Development to Transportation Equipment Using Flame-Retardant Magnesium Alloys

The target of this R&D theme was development of rare earth-free magnesium alloys with an excellent flame-retardant property and formability, and replacement of the body structure of high speed railway cars, in which aluminum materials are mainly used at present, with the magnesium alloys. In 2017, ISMA trial-manufactured a partial mockup structure (a length of 1 m), which is the world’s largest magnesium alloy section to date, with the same cross-sectional size as the current Shinkansen bullet train cars. Future plans include trial manufacture of a longer mockup of a partial structure and tests to verify safety in long-term use. In other work, ISMA also began development of an MI (Materials Integration) use technology for prediction of the performance and life of magnesium materials.

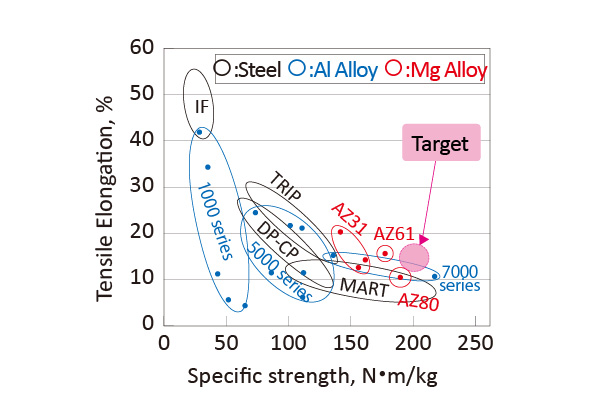

Target for development of magnesium alloys

Prototype of a partial high-speed railway car body made by flame-retardant Mg alloys

Research Achievements

Development of Flame-Retardant Magnesium Alloy

For an alloy for high speed extrusion, two high strength types and four types of fabricated materials were developed. Targets for strength and ductility were achieved in laboratory level by the end of FY 2015, and production at the mass production equipment size was possible by the end of FY 2017.

| Developed Mg alloys | Alloy composition(mass%) | |

|---|---|---|

| Mg alloy for high speed extrusion | AX41Alloy for extrusion use (easy formability) | Mg-4Al-1Ca |

| High strengthMg alloys | AX92Alloy for extrusion use | Mg-9Al-2Ca |

| AX81GAlloy for mediumand thick sheets | Mg-8Al-1Ca | |

| AX81SAlloy for thin sheets | Mg-8Al-1Ca | |

Types of developed alloys and fabricated materials

Trial Manufacture of Flame-Retardant Magnesium Alloy High Speed Railway Car Body Structure

A mockup partial car body structure with the same cross-sectional size as the current generation of Shinkansen bullet train cars and a length of 1 m, which is the world’s largest class, was trial-manufactured. In comparison with mass indicated in the drawing of an aluminum car, the magnesium alloy realizes a weight reduction of approximately 28 %.