Development of High Strength and High Toughness Aluminum Alloy and Application to Transportation Equipment

In order to develop a high strength aluminum alloy, ISMA developed an alloy composition and manufacturing process that increases the tensile strength of the existing material (A7150) by 25 % or more while maintaining the same ductility and toughness. A room temperature electrolytic refining process utilizing an ionic liquid was also developed as an alternative to the conventional Hall-Héroult process, which is an electric power-intensive technology. ISMA is also promoting development of high strength, high ductility automotive aluminum materials by using a multilayer structure, and is engaged in technology development of the basic manufacturing process, including the alloy composition, and study toward use in actual automotive members.

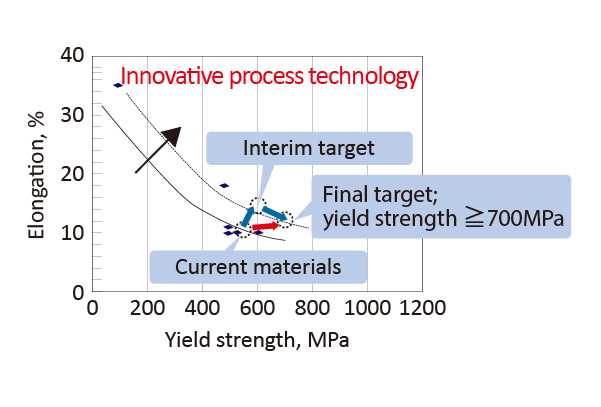

Target for development of aluminum alloy

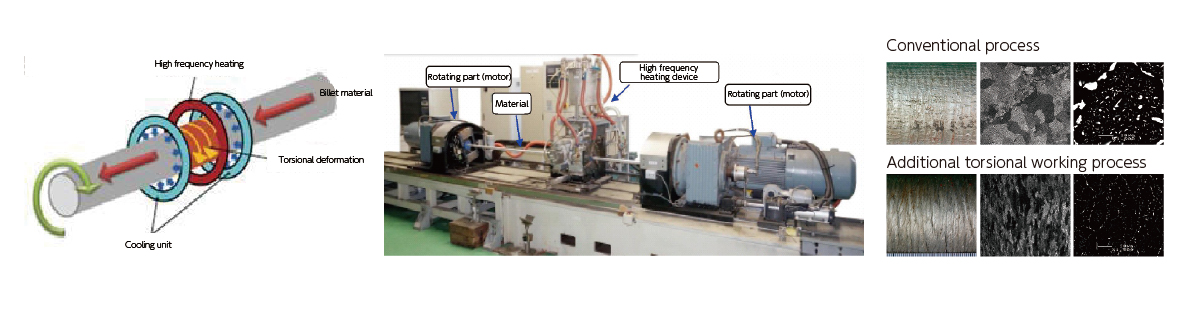

Precision controlled rolling device

Research Achievements

Development of High Strength and High Toughness Aluminum Alloy

Research Achievements

A large increase in strength was achieved by improvement of the metal microstructure by adding torsional working to the conventional process. The final targets for alloy development (0.2 % proof stress > 700 MPa, elongation > 12 %, same toughness) were achieved in FY 2017.

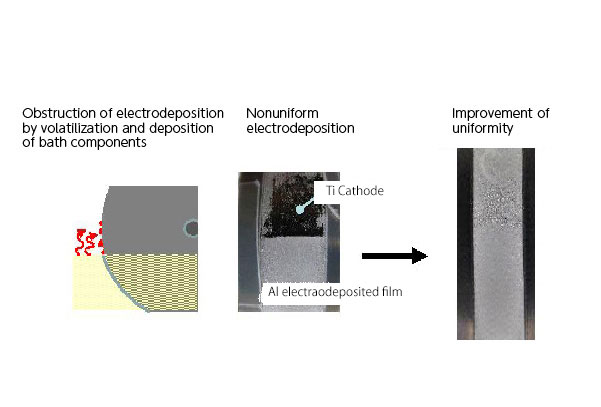

Development of Process Technology for New Aluminum Material Production Process

Research Achievements

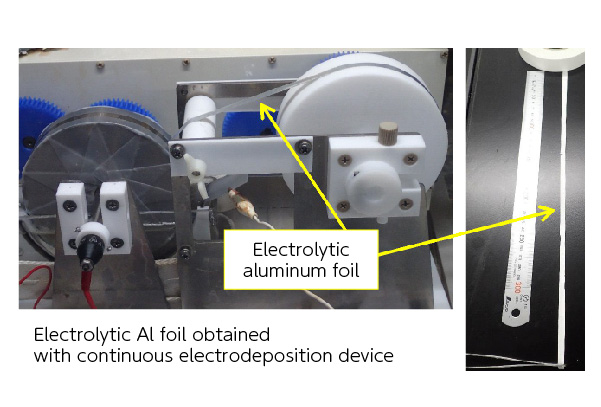

Aluminum in foil form was produced by using an independently-developed experimental drum-type continuous electrodeposition device, and a technology for recovery of the Al foil was established. The final targets are a production cost reduction of 25 % and impurity concentration of 10 ppm or less.

Experimental drum-type continuous electrodeposition device and its mechanism

Development of Multilayer Aluminum Alloy

Research Achievements

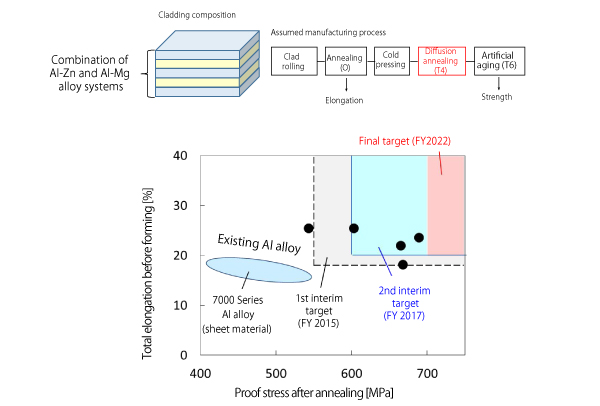

Properties approaching the final targets (proof stress after heat treatment: 700 MPa or higher, elongation before forming: 20 % or more) were obtained by optimization of the alloy design, clad structure and heat treatment conditions.

Goals and Level of Achievement of Multilayer Aluminum Alloy Development